Stainless simbi sintered sheet

Tsanangudzo

Material:Chikafu giredhi SS 304 316, mhangura, nezvimwe

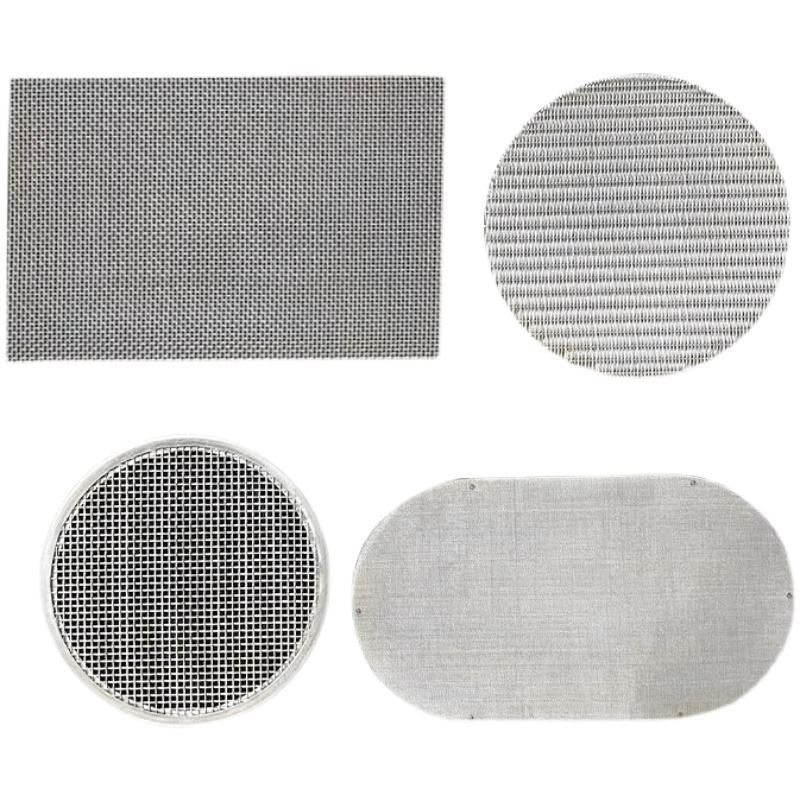

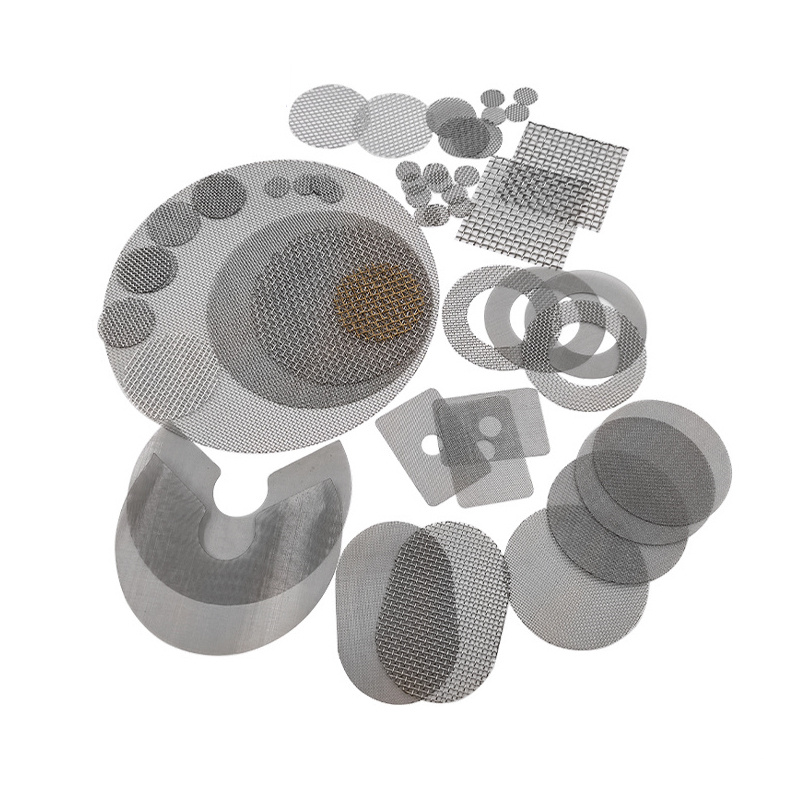

Chimiro:Round shape, rectangular shape toroidal shape, square shape, oval shape imwe yakakosha chimiro

Layer:Single layer, multi-layers

Chii chinonzi sintered mesh?

Iyo sintered waya mesh inogadzirwa nekurongedza akawanda-single-layer simbi isina simbi yakarukwa meshes emhando imwe chete kana akasiyana, mushure mekupisa, kudzvanya, kutenderedza uye mamwe maitiro, inogadzirwa nekupararira uye yakasimba mhinduro mushure mekupfurwa kwevacuum kusvika 1100 ° C. .Nyowani sefa zvinhu zvine yakakwira mechaniki simba uye kuomarara kwese.Iyo waya mesh yeimwe neimwe layer ine zvakaipira kusimba kwakaderera, kusimba kusimba, uye isina kugadzikana mesh chimiro, uye inogona zvine musoro kuenderana nekugadzira iyo void size, permeability uye simba hunhu hwechinyorwa, kuitira kuti ive yakanakisa kusefa kurongeka uye kusefa impedance., Mechanical simba, kupfeka kuramba, kupisa kupisa uye processability, kuita kwese kuri pachena kuri nani pane mamwe marudzi ezvesefa zvinhu senge sintered simbi poda, ceramics, faibha, sefa jira, nezvimwe.

Sintered waya mesh inorongedzerwa zvichienderana nematanho akasiyana uye waya mesh zvimiro, kunyanya kusanganisira mashanu-layer sintered waya mesh, akawanda-layer simbi sintered waya mesh, punched plate sintered waya mesh, square gole sintered waya mesh uye mat mhando sintered waya mesh.

Hunhu hwe sintered mesh

1. Kusimba kwakakwirira uye kusimba kwakanaka: Iine simba rakakwirira remagetsi uye simba rinomanikidzika, kushandiswa kwakanaka, welding uye kushanda kwegungano, uye nyore kushandisa.

2. Kusafanana uye kugadzikana kwakanyatsojeka: Kufanana uye kusingagumi kushandiswa kwesefa kunogona kuwanikwa kune zvose zvakagadziriswa, uye mesh haishanduki panguva yekushandiswa.

3. Yakawanda inoshandiswa nharaunda: Inogona kushandiswa munzvimbo yekushisa ye -200 ℃ ~ 600 ℃ uye kusefa kweasidhi uye alkali nharaunda.

4. Yakanakisa kuchenesa kushanda: yakanaka countercurrent yekuchenesa maitiro, inogona kushandiswa kakawanda, uye ine hupenyu hurefu hwebasa (inogona kucheneswa nemvura inopikisa, filtrate, ultrasonic, melting, kubika, nezvimwewo).

Pane matanho matatu ekugadzira sintering

1. Low tembiricha pre-kupisa danho.Panguva ino, kudzoreredza simbi, volatilization ye adsorbed gasi uye unyoro, kuora uye kubviswa kweanoumba mumiriri mune compact zvinonyanya kuitika;

2. Medium tembiricha kudziyisa sintering danho.Panguva ino, recrystallization inotanga kuitika.Muzvikamu, zviyo zvakaremara zvinodzorerwa uye zvakarongwa zvakare kuva zviyo zvitsva.Panguva imwecheteyo, oxides pamusoro pepamusoro inoderedzwa, uye particle interface inoumba mutsipa une sintered;

3. Kuchengetedza kupisa kwekushisa kwepamusoro kunopedzisa sintering stage.Kupararira uye kuyerera muchikamu ichi kunoitwa zvizere uye pedyo nekupedzwa, kuumba nhamba huru yevhavha yakavharwa, uye inoramba ichiderera, kuitira kuti saizi yepore uye nhamba yose yepores ideredzwe, uye kuwanda kwemuviri wakasvibiswa zvakanyanya. yakawedzera.