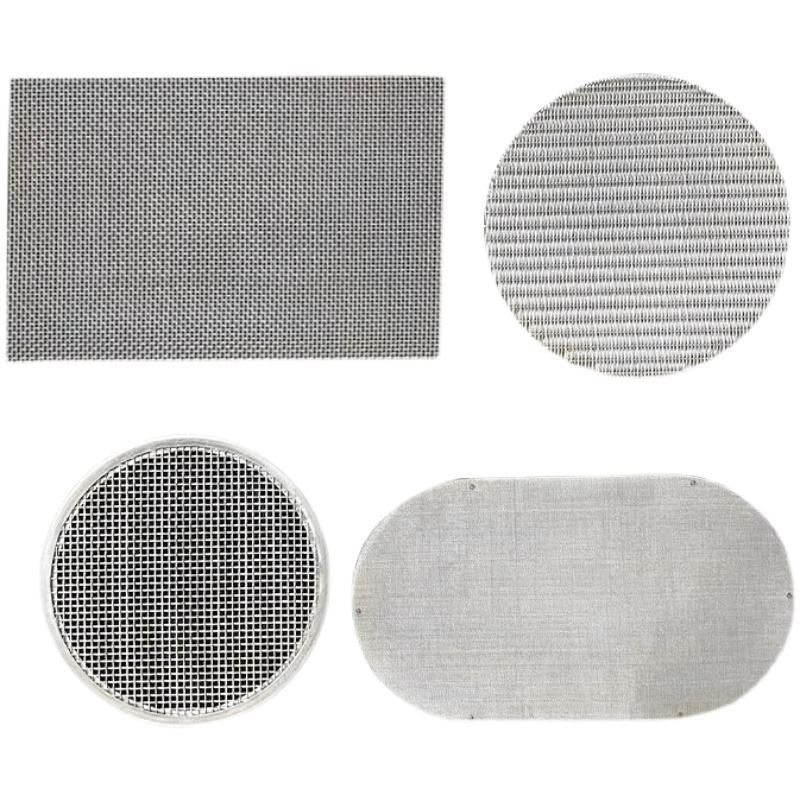

Stainless Simbi Kofi Sintered Tablets

Inoshanda Tutorials

1. Shingairira poda yekofi ne tamper

2. Isa muhukuru hwakakodzera hwemvura yekuparadzanisa mesh

3. Isa mubato wemushini wekofi pamusoro wekubika

4. Cherechedza mvura

Sei uchifanira kushandisa chechipiri chekugovera mvura network?

Chechipiri chekugovera mvura mambure zvinonyatsoparadzanisa hupfu hwekofi uye musoro wekubika kuti ugare wakachena

Hunhu hwe sintered mesh

1. Kusimba kwakakwirira uye kusimba kwakanaka: Iine simba rakakwirira remagetsi uye simba rinomanikidzika, kushandiswa kwakanaka, welding uye kushanda kwegungano, uye nyore kushandisa.

2. Kusafanana uye kugadzikana kwakanyatsojeka: Kufanana uye kusingagumi kushandiswa kwesefa kunogona kuwanikwa kune zvose zvakagadziriswa, uye mesh haishanduki panguva yekushandiswa.

3. Yakawanda inoshandiswa nharaunda: Inogona kushandiswa munzvimbo yekushisa ye -200 ℃ ~ 600 ℃ uye kusefa kweasidhi uye alkali nharaunda.

4. Yakanakisa kuchenesa kushanda: yakanaka countercurrent yekuchenesa maitiro, inogona kushandiswa kakawanda, uye ine hupenyu hurefu hwebasa (inogona kucheneswa nemvura inopikisa, filtrate, ultrasonic, melting, kubika, nezvimwewo).

Sintering kugadzira maitiro

1. Low tembiricha pre-kupisa danho.Panguva ino, kudzoreredza simbi, volatilization ye adsorbed gasi uye unyoro, kuora uye kubviswa kweanoumba mumiriri mune compact zvinonyanya kuitika;

2. Medium tembiricha kudziyisa sintering danho.Panguva ino, recrystallization inotanga kuitika.Muzvikamu, zviyo zvakaremara zvinodzorerwa uye zvakarongwa zvakare kuva zviyo zvitsva.Panguva imwecheteyo, oxides pamusoro pepamusoro inoderedzwa, uye particle interface inoumba mutsipa une sintered;

3. Kuchengetedza kupisa kwekushisa kwepamusoro kunopedzisa sintering stage.Kupararira uye kuyerera muchikamu ichi kunoitwa zvizere uye pedyo nekupedzwa, kuumba nhamba huru yevhavha yakavharwa, uye inoramba ichiderera, kuitira kuti saizi yepore uye nhamba yose yepores ideredzwe, uye kuwanda kwemuviri wakasvibiswa zvakanyanya. yakawedzera.